In modern confectionery production, efficiency and precision are essential. A Pillow Packaging Machine plays a crucial role in automating the wrapping of candies, ensuring uniformity while minimizing manual handling. This technology allows manufacturers to maintain product quality and speed up production, which is vital in competitive markets.

Streamlining Production Processes

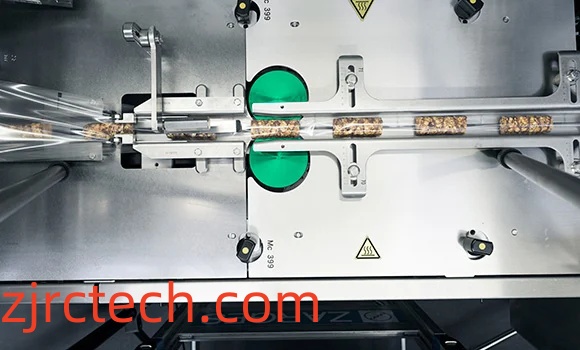

Automated pillow-style packaging improves workflow by reducing the time spent on repetitive tasks. Machines equipped with precise sensors and conveyors adjust seamlessly to different candy sizes and shapes. This adaptability ensures each piece is securely wrapped, maintaining visual appeal and protecting the product during transport.

Flexibility for Various Candy Types

One of the notable advantages of automated systems is their versatility. They can handle soft, hard, or coated candies, adapting to a wide range of packaging materials such as films or foils. This flexibility supports seasonal product variations, promotional items, and special editions without requiring major modifications to the machinery.

Enhanced Safety and Hygiene

Maintaining hygiene in candy production is a high priority. Automated packaging reduces direct contact between the product and operators, limiting the risk of contamination. Smooth surfaces and controlled movements also simplify cleaning, supporting compliance with food safety standards and improving overall workplace safety.

Cost and Operational Benefits

While initial investment in machinery might be significant, the long-term advantages are considerable. Automation decreases labor costs, minimizes packaging errors, and enhances production speed. Manufacturers benefit from consistent output and reduced material waste, which together contribute to operational efficiency and sustainability.

Applications Across the Industry

Pillow-style packaging is suitable for both small-scale confectionery makers and large factories. From individually wrapped candies to multi-pack assortments, the equipment can accommodate various packaging needs. Its adaptability allows businesses to expand production capabilities without sacrificing quality or efficiency.

Selecting the Right Machine

When choosing equipment, consider factors such as production volume, candy type, and maintenance requirements. Machines offering intuitive control panels, energy-efficient operation, and quick setup times are ideal. Evaluating how the equipment fits into the overall production line ensures optimal performance and return on investment.

Rongchuang's Commitment to Innovation

Rongchuang focuses on developing machinery that balances efficiency, reliability, and flexibility. Their Pillow Packaging Machine models are designed to meet diverse production needs, helping manufacturers optimize workflow while maintaining product quality. By integrating advanced technology, Rongchuang supports the growth and competitiveness of confectionery businesses.

For more details on automated candy packaging solutions, visit https://www.zjrctech.com/product/candy-pillow-packaging-machine/