In tailored garments and technical textiles, the hidden layer often dictates how a piece looks and performs — the Interlining provides shape, support, and durability without drawing attention, and designers rely on the Interlining to balance drape and structure during both production and wear. Understanding this unseen component early in the design process helps teams choose appropriate materials and methods that deliver the intended silhouette while meeting comfort and care expectations.

The functional role behind fabric structure

A supportive layer placed between outer fabric and inner lining changes how a garment hangs, how collars stand, and how cuffs retain their crispness. It can add body to lightweight fabrics or soften the hand of stiffer textiles. Beyond aesthetics, this layer helps distribute stress across seams, prevents premature wear at high-friction points, and can improve thermal insulation when specific fibers are used. Designers and manufacturers select these materials to achieve an intended balance between form and function.

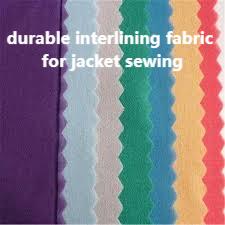

Types of constructions and when to use them

There are several construction approaches, each suited to particular applications. Bonded variants adhere to face fabrics using heat-activated agents, making them popular for collars and facings that require a clean finish. Sew-in versions offer more flexibility, favored where breathability and movement are priorities. Woven and non-woven options present trade-offs in stability, thickness, and tactile properties. Knowing which construction aligns with fabric weight, laundering requirements, and finished garment purpose is essential to avoid unwanted stiffness or loss of shape.

Material choices that influence performance

Fiber selection and processing determine how long the support layer will last and how it behaves in service. Natural fibers can offer softer hand and better moisture handling, whereas engineered fibers often excel in dimensional stability and resistance to shrinkage. Coatings and adhesives used in bonded formulations impact resilience and the garment’s response to repeated cleaning. Attention to these material properties during specification minimizes issues such as bubbling, delamination, or changes in drape after laundering.

Production techniques and quality control

Precision during assembly ensures the support layer performs as intended. Automated bonding systems, accurate temperature control, and calibrated pressure settings reduce the risk of inconsistent adhesion. For sew-in approaches, clean alignment and reliable stitch patterns prevent distortion. Inspection protocols typically include dimensional checks, adhesion testing, and visual assessment under varying light to detect defects. Consistent quality assurance protects brand reputation and reduces returns related to fit or finish problems.

Balancing sustainability and durability

Increasingly, manufacturers are exploring options that reduce environmental impact without sacrificing performance. Recycled fibers, lower-energy bonding processes, and adhesive chemistries with reduced volatile components are part of these efforts. Longevity also factors into sustainability: a support layer that extends a garment’s usable life by preserving shape and reducing replacements contributes positively to circularity goals. Collaboration between material scientists, designers, and production engineers helps identify solutions that are both responsible and fit for purpose.

Thoughtful specification and careful integration of support layers contribute significantly to garment quality, appearance, and longevity. By aligning material selection, construction method, and production controls with design intent and care regimes, teams can create products that satisfy consumers and stand up to routine use. For more on types, applications, and current developments, visit https://www.interlining-factory.com/news/what-is-interlining-types-applications-and-more.html