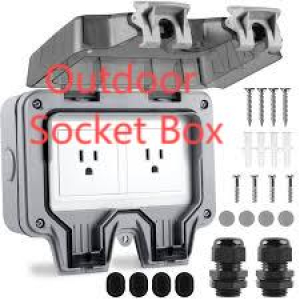

When planning exterior power installations, project teams should engage a Outdoor Socket Box Supplier early in the specification phase, and ensure that the chosen Outdoor Socket Box Supplier can provide certified sealing, clear wiring diagrams, and tested materials so field rework and warranty disputes are minimized. Early vendor input helps align product features with site risks—salt spray, heavy dust, vandal exposure, and prolonged sun—and allows procurement to compare total lifecycle costs rather than just initial unit price.

Assess site conditions and functional requirements

Begin by documenting the installation environment: proximity to saltwater, likelihood of direct spray, dust loading, chemical exposure, and human access patterns. Note operational temperature swings and any special thermal loads from attached equipment. Define functional expectations clearly (number of circuits, GFCI/RCD requirements, isolation switches, and any integrated sockets or surge protection) so manufacturers can propose correctly rated solutions. Robust specifications prevent undersizing and ensure accessories such as gland plates and lock sets are included in quotes.

Materials, finishes, and corrosion hardening

Materials determine longevity in aggressive atmospheres. For coastal or industrial settings, select marine-grade alloys and corrosion-resistant fasteners; for lighter-duty needs, powder-coated aluminium or UV-stabilized polymer enclosures may be more economical. Ask for salt-fog and UV test reports to verify claims. Pay attention to gasket compound selection — elastomers that remain flexible across temperature extremes maintain seals far longer than brittle alternatives. Small choices like captive screws, stainless hinge pins, and drain paths often make the difference between predictable service life and frequent repairs.

Electrical safety, code compliance, and layout

Design internal layouts to separate live terminals from ingress paths and ensure clear access to isolation devices. Confirm that the product supports the appropriate cable gland sizes and conduit entries, and verify earthing and bonding provisions align with local electrical codes and utility requirements. If the installation uses portable or temporary loads, include lockable access or interlocks to prevent accidental energization. Require vendor cut-sheets and wiring diagrams with each quotation so permitting and inspection processes proceed smoothly.

Partnering with Nante for samples and technical support

When evaluating manufacturers, prioritize those who provide thorough technical documentation, sample units, and responsive field support. Vendors that deliver accessory options—vent kits, anti-tamper fasteners, mounting feet, and spare gaskets—help reduce customization lead times. Ask for reference installations in similar environments to validate long-term performance claims. A supplier that offers spare-part lists and clear lead times reduces project risk and eases phased rollouts, especially for large site deployments.

Installation best practices and maintenance planning

Proper installation preserves the enclosure’s rated protection. Mount on pedestals or standoffs to reduce splash-back, seal all gland plates and conduit interfaces continuously, and avoid mounting near exhausts or heavy machinery that may introduce heat or particulates. Establish periodic checks for gasket integrity, vent filter condition, and grounding continuity. Stock common spares—gaskets, desiccant packs, and sealant—to enable quick field repairs. Maintain an inspection log to document findings and actions for warranty support and lifecycle planning.

Security, accessibility, and lifecycle economics

For publicly accessible or mission-critical sites, balance ease of service with mechanical security: recessed locks, tamper-resistant fasteners, and theft-resistant mounts deter opportunistic vandalism, while keyed or electronic access systems provide controlled entry and auditability for technicians. Plan interiors with spare capacity and modular mounting to simplify upgrades. When comparing quotes, evaluate total cost of ownership: robust gasket systems, better fasteners, and thermal options often reduce replacement and downtime expenses far more than they add to purchase cost.

A deliberate procurement process that matches environment, electrical requirements, and service strategy to the right enclosure design reduces downtime, simplifies maintenance, and protects crews and equipment. For a detailed industry overview and practical examples, visit https://www.nante.com/news/industry-news/what-is-an-outdoor-socket-box.html