Water treatment plants are the backbone of sustainable living in the UAE. In a region where freshwater resources are limited and demand continues to rise across residential, commercial, and industrial sectors, efficient water treatment infrastructure is not optional—it is critical. At the heart of this infrastructure lies one essential component that often works quietly behind the scenes: the industrial valve.

Industrial valves play a decisive role in controlling, regulating, and directing the flow of water throughout treatment plants. From desalination facilities along the coast to sewage treatment plants serving growing urban centers, valves ensure processes run safely, efficiently, and reliably.

The Role of Industrial Valves in Water Treatment

Water treatment is not a single-step operation. It involves multiple stages such as intake, filtration, chemical dosing, sedimentation, disinfection, and distribution. At each stage, industrial valves are responsible for managing pressure, isolating systems, preventing backflow, and enabling precise flow control.

In UAE water treatment plants, valves must perform under demanding conditions. High salinity, temperature variations, continuous operation, and strict regulatory requirements all place significant stress on valve systems. This makes the selection of the right industrial valve not just a technical decision, but a long-term operational investment.

Key Applications Across Treatment Stages

During the raw water intake stage, industrial valves regulate the initial flow of seawater or groundwater into the plant. These valves must handle large volumes while resisting corrosion, especially in desalination plants where seawater exposure is constant.

In filtration and sedimentation processes, valves control the movement of water between tanks and filters. Accurate flow regulation is essential here to ensure effective removal of suspended solids and contaminants. A poorly performing valve at this stage can compromise water quality and increase maintenance costs.

Chemical dosing systems rely heavily on precision. Industrial valves used in chlorination, pH adjustment, and coagulant dosing must offer tight shutoff and consistent control. Even minor inaccuracies can affect treatment efficiency or lead to chemical wastage.

Finally, in treated water distribution and wastewater discharge, valves manage pressure and direction, ensuring safe transport through pipelines while protecting equipment from surges or backflow.

Common Types of Industrial Valves Used

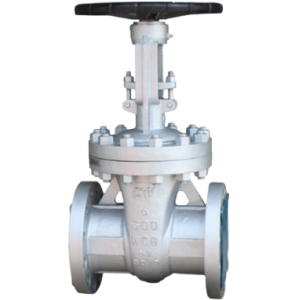

Different valve types are used depending on the application and operating conditions. Gate valves are commonly found in isolation duties where full flow or complete shutoff is required. Their simple design makes them suitable for large pipelines in water treatment plants.

Butterfly valves are widely used in the UAE due to their compact size and cost efficiency. They are ideal for flow regulation in medium to large diameter pipes and are often preferred in desalination and municipal water systems.

Ball valves are chosen for applications requiring quick shutoff and minimal leakage. Their durability and ease of operation make them suitable for chemical dosing lines and auxiliary systems.

Check valves play a crucial safety role by preventing reverse flow, protecting pumps and sensitive equipment from damage. In water treatment plants, they are essential wherever pressure fluctuations are expected.

Control valves, often automated, are increasingly important in modern UAE facilities that rely on smart monitoring and process automation. These valves enable precise regulation based on real-time data, improving efficiency and reducing manual intervention.

Benefits of High-Quality Industrial Valves

Using the right industrial valve directly impacts plant performance. Reliable valves reduce water losses, prevent contamination, and minimize downtime. In the UAE, where operational continuity is vital, valve failure can disrupt water supply and lead to costly emergency repairs.

High-quality valves also contribute to energy efficiency. Smooth flow control reduces pump load and pressure drops, lowering overall power consumption. Over time, this translates into significant operational savings.

Durability is another key benefit. Valves designed for harsh environments offer longer service life, reducing replacement frequency and maintenance costs. For water treatment operators, this reliability supports long-term planning and regulatory compliance.

Choosing the Right Valve Supplier in the UAE

Selecting an industrial valve is only part of the equation. Choosing the right supplier or manufacturer is equally important. UAE-based water treatment projects often require valves that meet international standards while being readily available for maintenance and support.

A reliable supplier understands local operating conditions, including water chemistry, climate, and regulatory requirements. They can recommend suitable materials such as ductile iron, stainless steel, or specialized coatings to combat corrosion and wear.

This is where experienced trading partners like AL Zerwa Trading naturally fit into the supply chain. Known in the UAE industrial sector for providing dependable flow control solutions, they support water treatment projects with products that align with both technical requirements and long-term reliability. Rather than focusing only on sales, such suppliers add value through technical guidance and consistent after-sales support.

The Growing Importance of Valves in UAE Water Infrastructure

As the UAE continues to invest in desalination plants, wastewater recycling, and smart water networks, the importance of industrial valves will only increase. Advanced treatment technologies demand equally advanced flow control systems that can integrate with automation and monitoring platforms.

Sustainability goals are also reshaping valve selection. Leak-proof designs, energy-efficient operation, and long service life are no longer optional features—they are expected standards in modern water treatment facilities.

Conclusion

Industrial valves are a critical component in the success of water treatment plants across the UAE. From controlling raw water intake to ensuring safe distribution of treated water, the performance of each valve directly affects efficiency, safety, and reliability. Understanding valve applications, selecting the right type, and partnering with a trusted supplier can make a measurable difference in plant operations.

For engineers, contractors, and industrial buyers, the smartest approach is to work with a reliable manufacturer or supplier in the UAE who understands local challenges and global standards. Choosing the right partner today helps ensure uninterrupted water treatment performance for years to come.