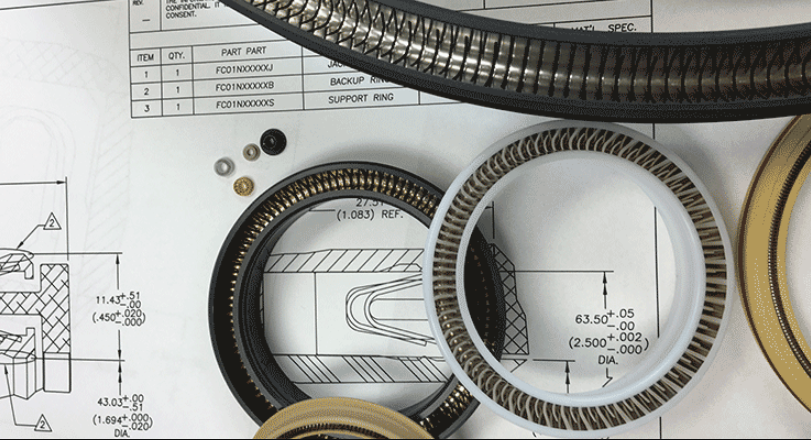

Spring energized seals are high-performance sealing solutions designed for demanding environments where conventional elastomer seals fail. They are widely used in industries that require reliable sealing under extreme pressures, temperatures, and chemical exposure. This article explains what spring energized seals are, how they work, their advantages, common applications, and material options.

What Is a Spring Energized Seal?

A spring energized seal is a sealing device made from a high-performance polymer jacket (typically PTFE or similar materials) combined with a metal spring embedded inside the seal. The spring continuously applies force to the seal lip, ensuring consistent contact with the mating surface.

Unlike standard O-rings that rely on system pressure alone, spring energized seals maintain sealing force even in low-pressure or vacuum conditions. This makes them ideal for critical applications where leakage is unacceptable.

How Spring Energized Seals Work

The internal spring provides constant radial or axial load to the seal jacket. This force:

-

Compensates for wear over time

-

Maintains sealing integrity during pressure fluctuations

-

Ensures tight sealing in static and dynamic conditions

When system pressure increases, it works together with the spring to enhance the sealing effect rather than replacing it.

Key Benefits of Spring Energized Seals

1. Excellent Sealing Performance

Spring energized seals deliver consistent sealing even at zero or very low pressure, making them superior to conventional elastomer seals.

2. Wide Temperature Resistance

These seals perform reliably in extreme temperatures, often ranging from -200°C to +300°C, depending on material selection.

3. Chemical Compatibility

PTFE-based jackets resist aggressive chemicals, solvents, and corrosive fluids.

4. Low Friction and Wear

The low coefficient of friction reduces wear, extending service life and improving efficiency in dynamic applications.

5. Long Service Life

The spring compensates for material wear, ensuring reliable performance over extended periods.

Types of Springs Used

Different spring designs are selected based on application requirements:

-

Cantilever Spring – Ideal for low friction and moderate loads

-

Helical Coil Spring – Provides uniform load distribution

-

Canted Coil Spring – Excellent for dynamic and high-pressure sealing

Each spring type influences load, flexibility, and sealing performance.

Common Materials Used

Seal Jacket Materials

-

PTFE (Virgin or Filled)

-

UHMW-PE

-

PEEK

-

Polyimide

Spring Materials

-

Stainless Steel (304, 316)

-

Elgiloy®

-

Inconel®

Material selection depends on pressure, temperature, chemical exposure, and motion type.

Applications of Spring Energized Seals

Spring energized seals are used across many industries, including:

-

Oil & Gas – Downhole tools, valves, and pumps

-

Aerospace – Actuators and hydraulic systems

-

Semiconductor Manufacturing – Vacuum chambers and wafer processing

-

Medical Devices – Sterilization-resistant sealing solutions

-

Chemical Processing – Reactors, mixers, and aggressive media handling

Static vs Dynamic Applications

-

Static Sealing: Used in flanges and housings where no movement occurs

-

Dynamic Sealing: Suitable for reciprocating, rotating, and oscillating motion

Spring energized seals perform exceptionally well in both cases due to their self-energizing design.

Advantages Over Conventional Seals

| Feature | Spring Energized Seal | O-Ring |

|---|---|---|

| Low-pressure sealing | Excellent | Limited |

| Chemical resistance | Very high | Moderate |

| Temperature range | Wide | Narrow |

| Wear compensation | Yes | No |

Conclusion

Spring energized seals are advanced sealing solutions engineered for extreme and demanding environments. Their ability to maintain consistent sealing force, resist harsh chemicals, and perform across wide temperature ranges makes them an excellent choice for critical industrial applications. While they may have a higher initial cost than traditional seals, their durability, reliability, and performance often result in lower long-term maintenance and operational costs.