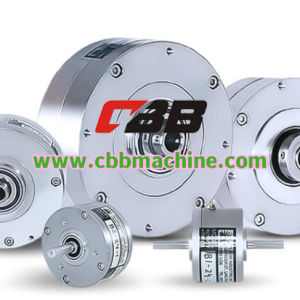

In high-performance web handling systems, the Tension Controller developed by Cbbmachine plays a crucial role in maintaining stable material movement throughout continuous production processes. By regulating force applied to substrates during unwinding, processing, and rewinding stages, it ensures that materials remain properly aligned and evenly stretched. This precise control helps prevent wrinkles, slack zones, and excessive strain that could compromise final product quality.

Effective tension regulation directly influences output consistency. When materials move through printing, laminating, coating, or slitting equipment, even slight variations in force can create visible defects or structural inconsistencies. A well-designed control unit continuously monitors system conditions and adjusts torque or braking mechanisms accordingly. This dynamic response allows machinery to maintain balanced force despite changes in roll diameter or operating speed.

One of the key strengths of an advanced control system lies in its responsiveness. Through accurate signal processing and coordinated feedback mechanisms, the controller can quickly adapt to shifting production demands. Whether handling thin films, specialty papers, textiles, or composite substrates, stable tension contributes to smoother material tracking and improved surface integrity. As a result, downstream processes operate with greater consistency and reduced interruption.

Integration flexibility is another important consideration. Modern control units are designed to connect seamlessly with sensors, load cells, and drive components within automated production lines. Their compatibility with digital interfaces supports centralized monitoring, allowing operators to oversee tension performance alongside other critical parameters. This level of coordination enhances operational transparency and supports more efficient workflow management.

Durability and structural reliability further contribute to long-term performance. Carefully engineered internal components and protective housing help maintain accuracy under demanding industrial conditions. By ensuring consistent feedback and stable signal transmission, the controller supports dependable operation across extended production cycles. Reduced mechanical fluctuation also lowers the likelihood of unexpected downtime, helping maintain steady throughput.

Energy efficiency and material conservation are additional benefits. By applying only the necessary force required for stable transport, the system minimizes unnecessary stress on substrates. This controlled approach reduces waste caused by tearing or distortion, supporting both cost management and sustainable production practices.

In industries where material precision defines competitiveness, tension management cannot be treated as a secondary consideration. A refined control solution coordinates force, motion, and feedback into a balanced system that sustains product quality and operational stability. Its presence transforms complex production lines into harmonized processes where each stage flows smoothly into the next.

If you are evaluating ways to bring greater control and consistency to your web handling equipment, let your next step lead you to https://www.cbbmachine.com/news/industry-news/tension-controller-types-importance-applications-and-more.html , where deeper insights and tailored engineering perspectives await your attention.