Crosslinked Shrink Film is engineered to withstand a wide range of packaging demands. When tested under real packaging conditions, this material demonstrates performance that supports high-output operations and product consistency. Manufacturers often ask whether crosslinked options offer measurable advantages during real use—not just in theory.

Crosslinking changes the film’s molecular makeup, increasing its durability and resistance to heat. In active production environments, this results in a film that is less likely to tear or warp, even when used on items with sharp corners or under tension. For packaging lines with variable speeds or changing product shapes, crosslinked shrink film offers steady results with fewer adjustments.

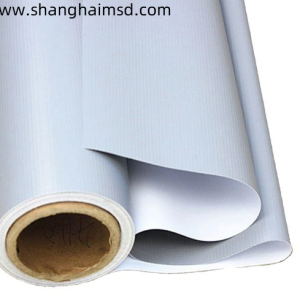

jtpackage focuses on providing materials designed for practical, everyday use. Our crosslinked shrink film is tested in packaging lines that mirror real industrial conditions—ranging from fast-paced wrapping systems to applications that require accurate seal performance. This ensures compatibility and reliability where it counts.

Operators also report improved performance with thinner film gauges, contributing to potential material savings while retaining film strength. Whether applied to consumer products, bundled items, or oddly shaped goods, the film shrinks evenly, providing a clear finish and a secure hold.

Companies considering a change in their packaging materials can benefit from understanding how crosslinked shrink film behaves in their actual environment. jtpackage is committed to helping clients choose solutions based on experience and practical feedback.

For more details on how jtpackage’s crosslinked shrink film fits into your operation, visit:

https://www.jtpackage.com/product/