The textile industry continues to grow with innovations that improve fashion and function. Among the essential materials is Interlining , a hidden but powerful component that shapes garments and improves durability. By supporting structure and enhancing design, interlining has become indispensable across the clothing industry. Companies such as interlining-factory ensure this material evolves with modern requirements and industry advancements.

What Makes This Layer Essential in Garment Production

This supportive layer provides stability to fabrics, allowing designers to craft garments that hold shape and maintain a professional appearance. Collars, cuffs, waistbands, and other structured areas benefit significantly. Without it, clothing would appear limp and unfinished. It also adds comfort, ensuring that garments meet consumer expectations for both aesthetics and practicality.

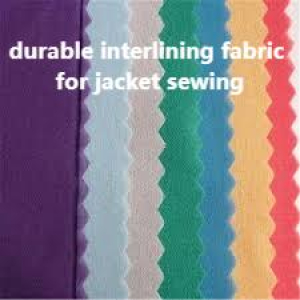

Exploring the Different Types

Several variations are used across global production. Fusible options rely on adhesive bonding, making them efficient for large-scale manufacturing. Sew-in types remain the preferred choice for delicate or premium fabrics. Nonwoven, woven, and knit forms each provide distinct flexibility and texture. Choosing the appropriate type is crucial for achieving a balance of strength, softness, and drape in the final garment.

Sustainability and Innovation in Production

The demand for eco-friendly textiles has reshaped how manufacturers approach production. Recycled fibers, biodegradable adhesives, and water-efficient techniques are being adopted to reduce environmental impact. Interlining-factory, as an example of innovation, demonstrates how a traditional product can meet modern sustainability goals while maintaining quality and performance.

Brand Spotlight: Interlining-Factory and Industry Standards

Quality and consistency are fundamental to the textile supply chain. Interlining-factory has become a trusted name, ensuring reliable materials that align with international standards. With advanced technology and strict quality controls, the brand supports both industrial production and bespoke tailoring, reinforcing its role in global fashion and technical textiles.

Future Outlook: The Expanding Role of This Material

Looking forward, this fabric layer is expected to integrate more functionality, from moisture control to smart textile applications. It is already extending beyond fashion into uniforms, protective wear, and home furnishings. Its adaptability guarantees a lasting role in shaping garments and other textile-based products across industries.

In conclusion, this invisible component is much more than a structural aid—it is a driver of quality, durability, and innovation in textiles. For further insights into types, uses, and future trends, visit https://www.interlining-factory.com/news/what-is-interlining-types-applications-and-more.html .