Production facilities rely heavily on conveyor systems to maintain consistent flow and efficiency. Any downtime can quickly lead to bottlenecks and lost productivity, making the reliability of each component critical.

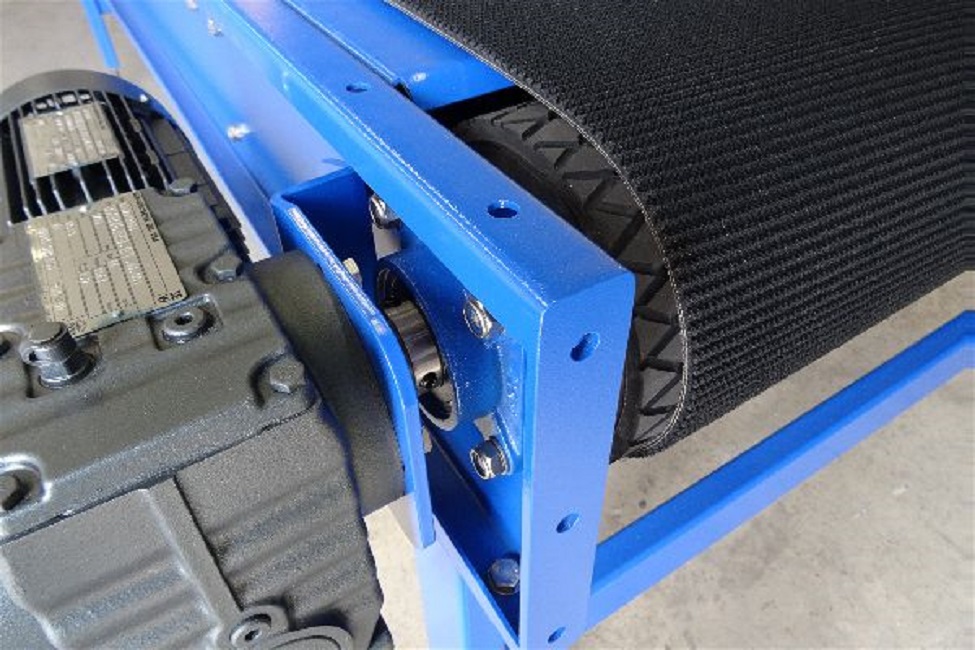

The performance of a conveyor line often depends on the quality of its belt conveyor parts. From belts and rollers to motors and frames, every element has a role in keeping operations smooth. Understanding these parts and their functions helps ensure systems remain reliable and adaptable to production demands.

Why Belt Conveyor Parts Matter in Production

Every conveyor system is only as strong as its weakest part. When components begin to fail, the impact can ripple through the entire line. Reliable conveyor parts maintain product flow, reduce the risk of breakdowns, and extend the life of the equipment. They also minimize costly downtime and ensure that production goals are consistently met.

Core Belt Conveyor Components

A standard conveyor system includes several key components:

- Belts: The surface that carries products, available in a variety of materials to handle different loads.

- Pulleys: Drive and guide the belt while maintaining proper tension.

- Rollers: Support and stabilize the belt during operation.

- Frames: Provide structural strength and alignment.

- Motors and drives: Deliver the power that keeps the conveyor moving.

Each part works together to ensure smooth and consistent performance across production lines.

Conveyor Accessories That Enhance Performance

Beyond the core components, conveyor accessories can improve system functionality:

- Side guides: Keep products aligned on the belt.

- Sensors: Monitor product flow and detect jams.

- Cleaning systems: Reduce buildup and extend belt life.

- Safety guards: Protect operators and equipment from accidents.

These accessories are not optional additions—they play a critical role in enhancing efficiency and ensuring compliance with safety standards.

Signs It’s Time to Replace Conveyor Parts

Like all machinery, conveyors experience wear over time. Some common signs that parts may need replacement include:

- Belts showing cracks, fraying, or slipping during operation

- Rollers producing excess noise or failing to spin freely

- Motors overheating or struggling to maintain a consistent speed

- Pulleys or bearings showing visible wear or misalignment

The timely replacement of these parts prevents unexpected breakdowns and extends the system's lifespan.

Benefits of Using Quality Conveyor Components

Investing in durable and reliable parts delivers long-term benefits:

- Reduced downtime through consistent performance

- Lower maintenance costs from extended component life

- Improved safety and compliance in production environments

- Greater adaptability for future production requirements

High-quality parts not only protect equipment but also support higher throughput and efficiency.

Keeping Production Reliable with the Right Partner

The efficiency of a conveyor system depends on the quality of its conveyor components. From essential belts and rollers to value-adding accessories, each part contributes to the overall performance of the line. Reliable replacements ensure long-term productivity and fewer interruptions.

Conovey supplies durable and high-performing belt conveyor solutions tailored to modern production environments. By choosing Conovey as a trusted partner, manufacturers gain access to dependable parts, accessories, and support services that keep production moving without compromise.

Contact Conovey today to learn more about sourcing quality conveyor parts and components for long-term operational success.